Welding Cell With PLC And IIOT

Industrial Welding Robocell from Hytech Didactic consists of 3 individual experiment tables and an industrial welding robot with minimum reach of 1000mm. Central Control Unit equipped with PLC, HMI and IIOT is integrated with Welding Robot. Robot can be programmed from a teach pendant or from an offline programming software which can also act as a digital dynamic twin.

Separate TV Screen displaying the digital dynamic twin is also provided along with this setup.

Separate mobile unit in aluminum extrusions is provided for welding controller, stepdown transformer and Robot controller. Trolley for gas cylinder and mounting arrangement for feeder cable are also provided along with the setup.

Each experiment table is made up of mild steel and the top surface is covered with an aluminum sheet for ease of removal of welding splatter. Robot is equipped with an industrial welding source such as Fronius.

I/O link communication with Smart light provides industrial experience to users. Communication between Robot Controller and machine control panel is via profinet.

Table 1: Basic Weld Joints Table

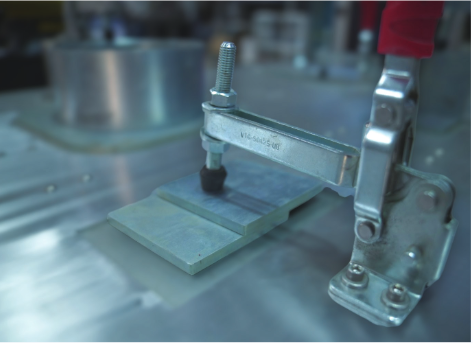

This table is provided with mechanical clamping arrangements. Various types of joints can be welded on this table.

Text on screen during voiceover:

Butt joint

Corner joint

Edge joint

Lap joint

TEE - joint

Table 2: Automated Welding Table

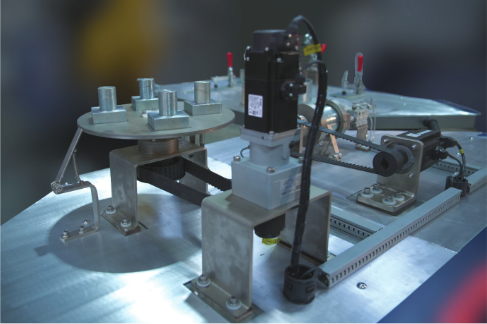

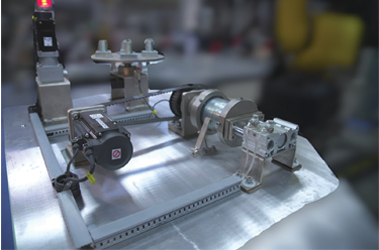

Setup 1: Servo Motor Based Automated Welding Module

This table is provided with two separate automated welding arrangements. Setup 1 consists of an indexing table equipped with AC Servo Motor. User can program Servo Motor from PLC and integrate the automation process with Welding Robot to carry out automated welding of jobs. Robot can weld one job on the indexing table and wait for the servo motor to be indexed from PLC and then carry out the welding of next job at the same location.

Setup 2: Servo Motor Based Circular Welding Module

This table is provided with two separate automated welding arrangements. Setup 1 consists of an indexing table equipped with AC Servo Motor. User can program Servo Motor from PLC and integrate the automation process with Welding Robot to carry out automated welding of jobs. Robot can weld one job on the indexing table and wait for the servo motor to be indexed from PLC and then carry out the welding of next job at the same location.

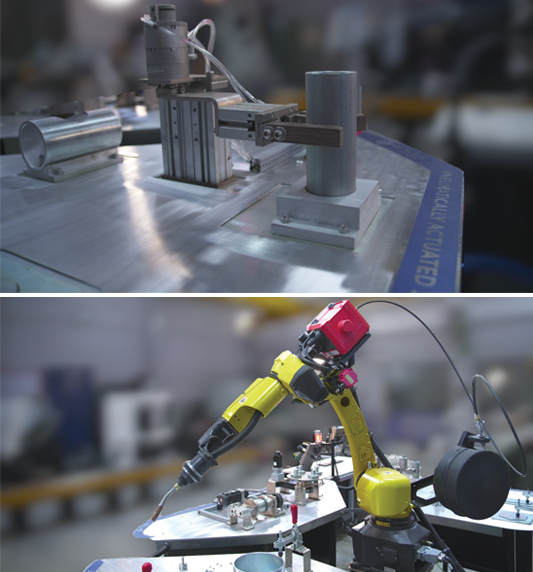

Table 3: Automated 3 Dimensional Circular Welding Table

This table is equipped with pneumatically actuated pick and place unit which picks up first pipe and places it inside the second pipe. Pick and place arrangement is controlled through PLC. Robot then carries out 3 dimensional circular welding of two hollow pipes.

Conventional Robotic Welding

Automated Robotic Welding by integrating Robot - PLC - HMI and Servo Motor

Automated Robotic Welding by integrating Robot - PLC - HMI and Pneumatic Valves Offline Programming of Welding Cell

Digital Dynamic Twin

I/O Link Connectivity with Smart Light

Alumnum sheets on all tables for easy removal of weld splatter

Major Components

| COBOT | Fanuc Arc Mate with Minimum 1000mm reach and 12KG Payload |

| PLC | Siemens S7 1200 / Mitsubishi FX5 |

| HMI | IIOT Based HMI / Siemens KTP 700 / Mitsubishi GS |

| Welding Source | Fronius / Lincoln |

| Operation | Through Teach Pendant and Hardware Operation Panel |

| Connectivity | i/o link based and profinet |

| OLP Software | Fanuc Roboguide / Siemens Technomatix |