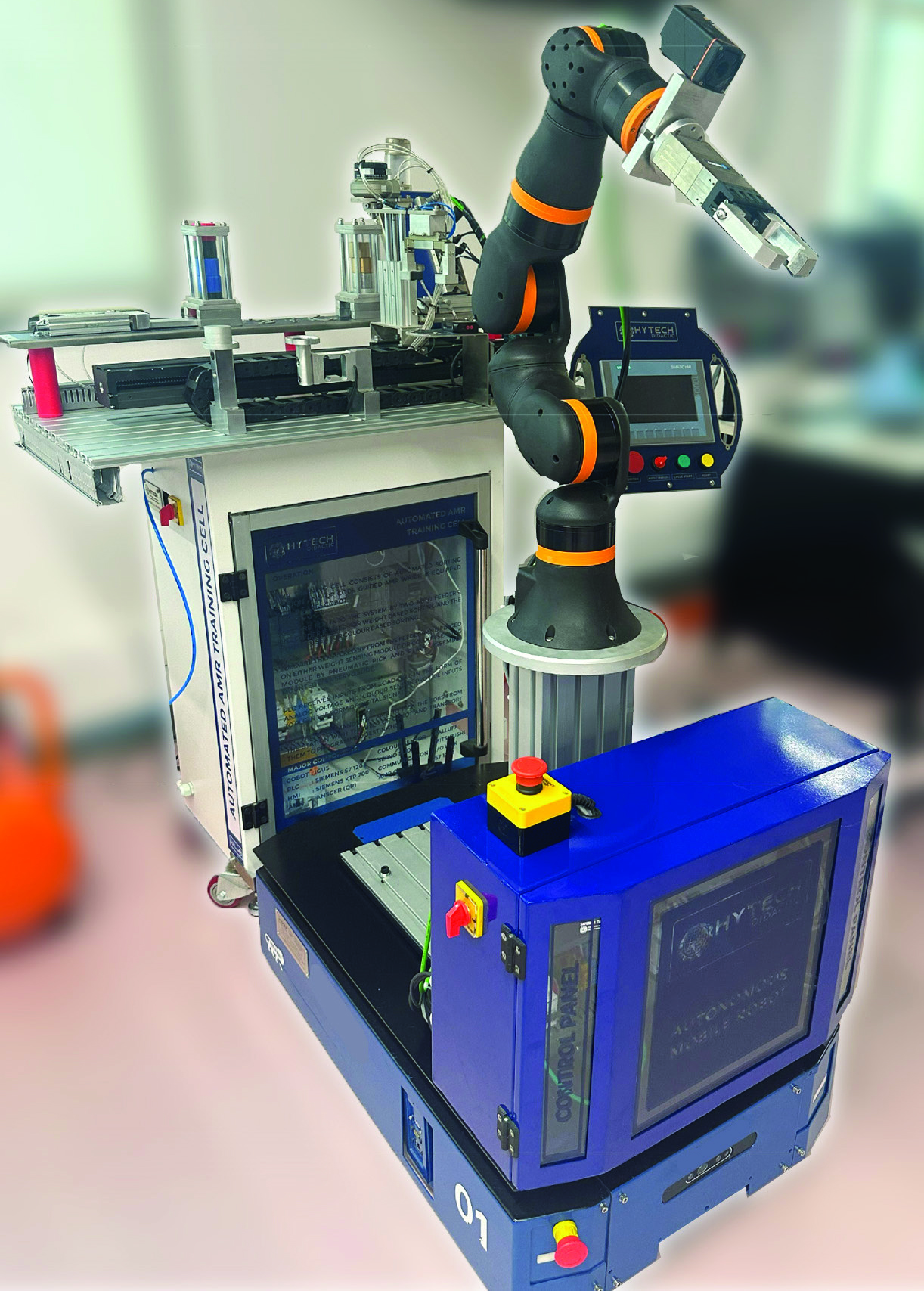

AMR With Industrial Automation Station And COBOT

Hytech Didactic AMR Training cell is designed to provide hands on experience to students on industrial AMR applications and its integration with industrial automation components such as COBOT, PLC – HMI and Vision System.

AMR is equipped with a Lidar sensor and programmed with ROSS. Automation station is a separate unit which is programmed and operated with Siemens PLC and HMI. AMR is mounted with a six axes Cobot and a vision system for efficient pick up of jobs.

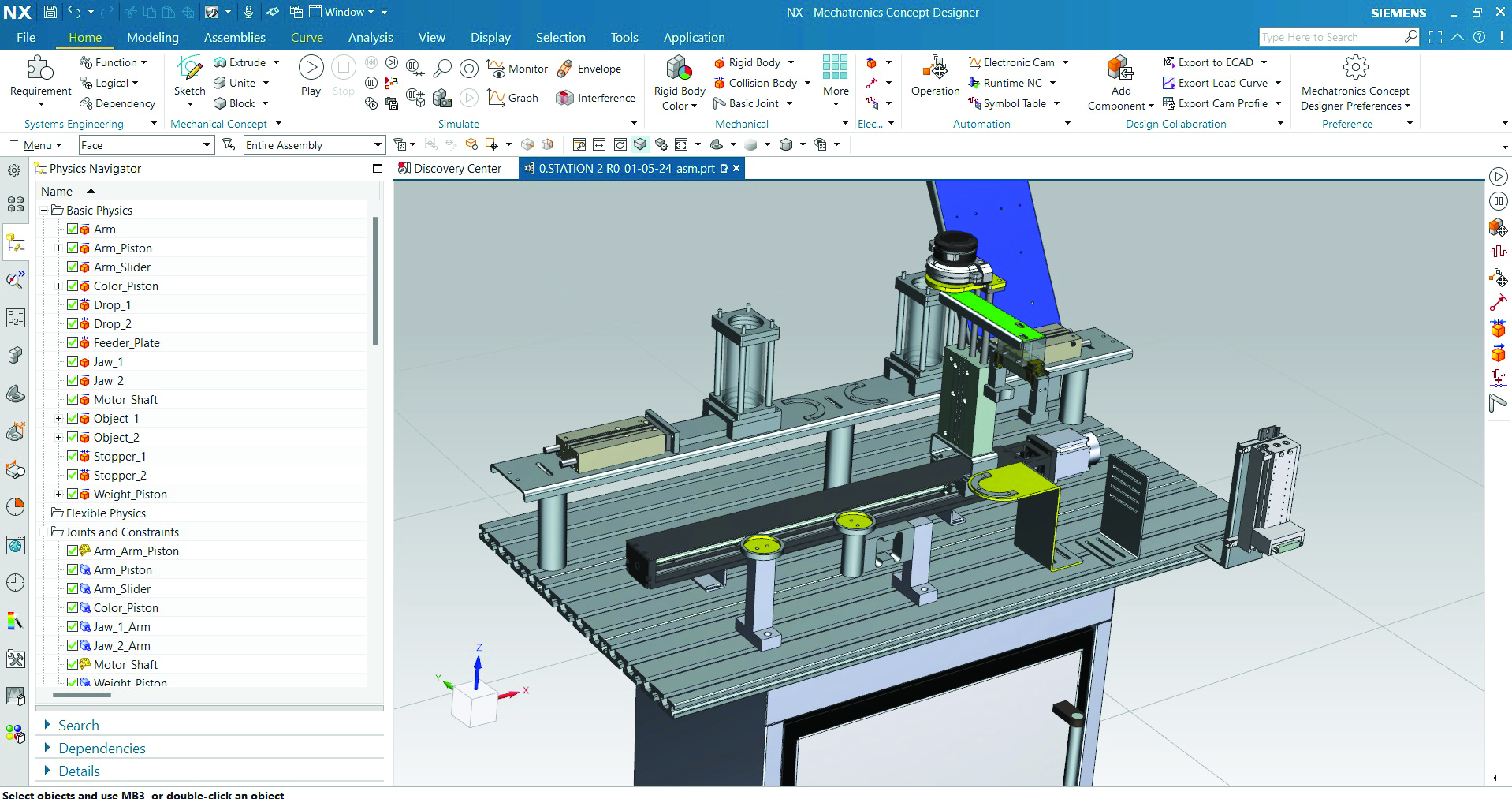

This setup is integrated with Mechatronics Concept Designer software for remote commissioning and process simulation using digital twin.

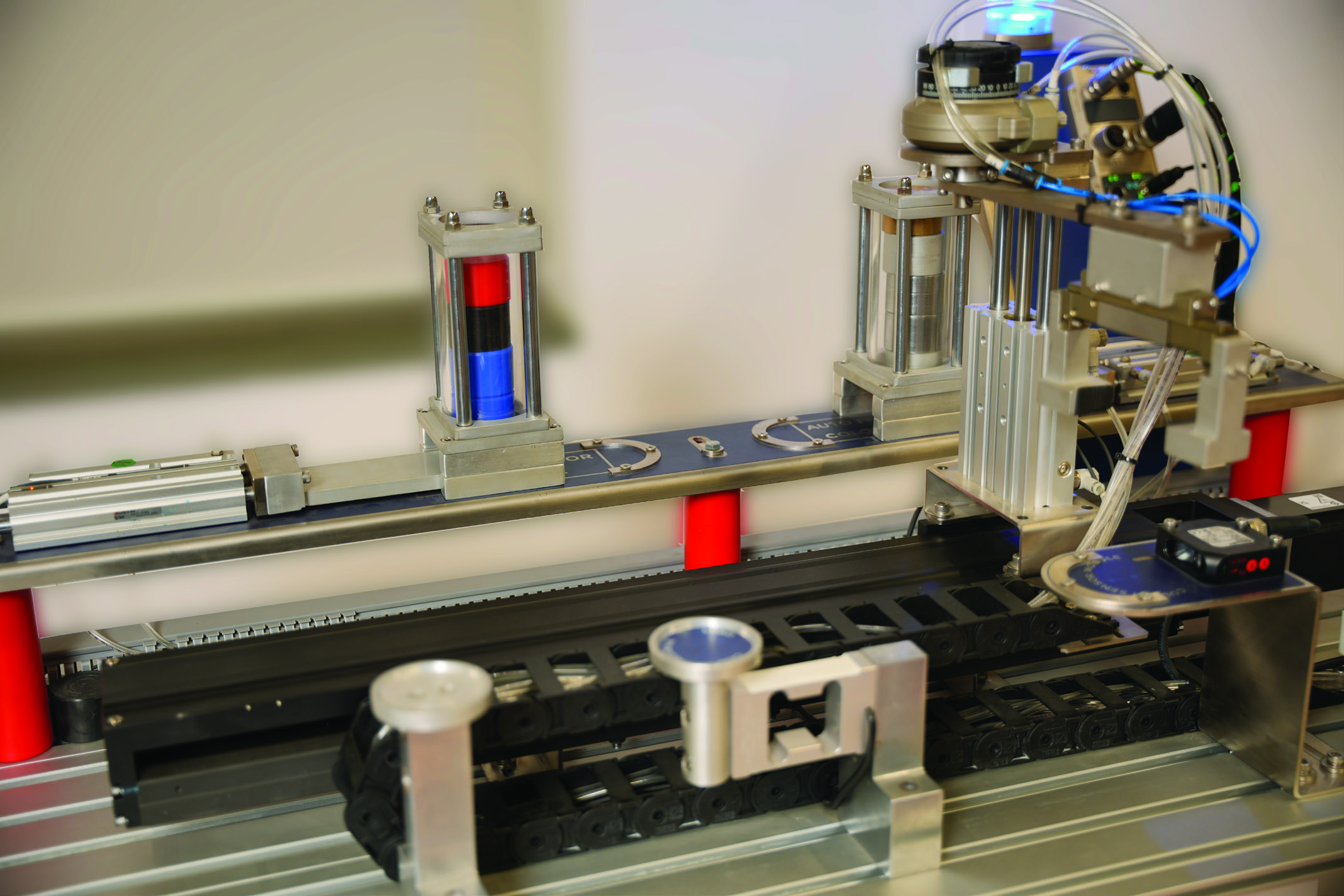

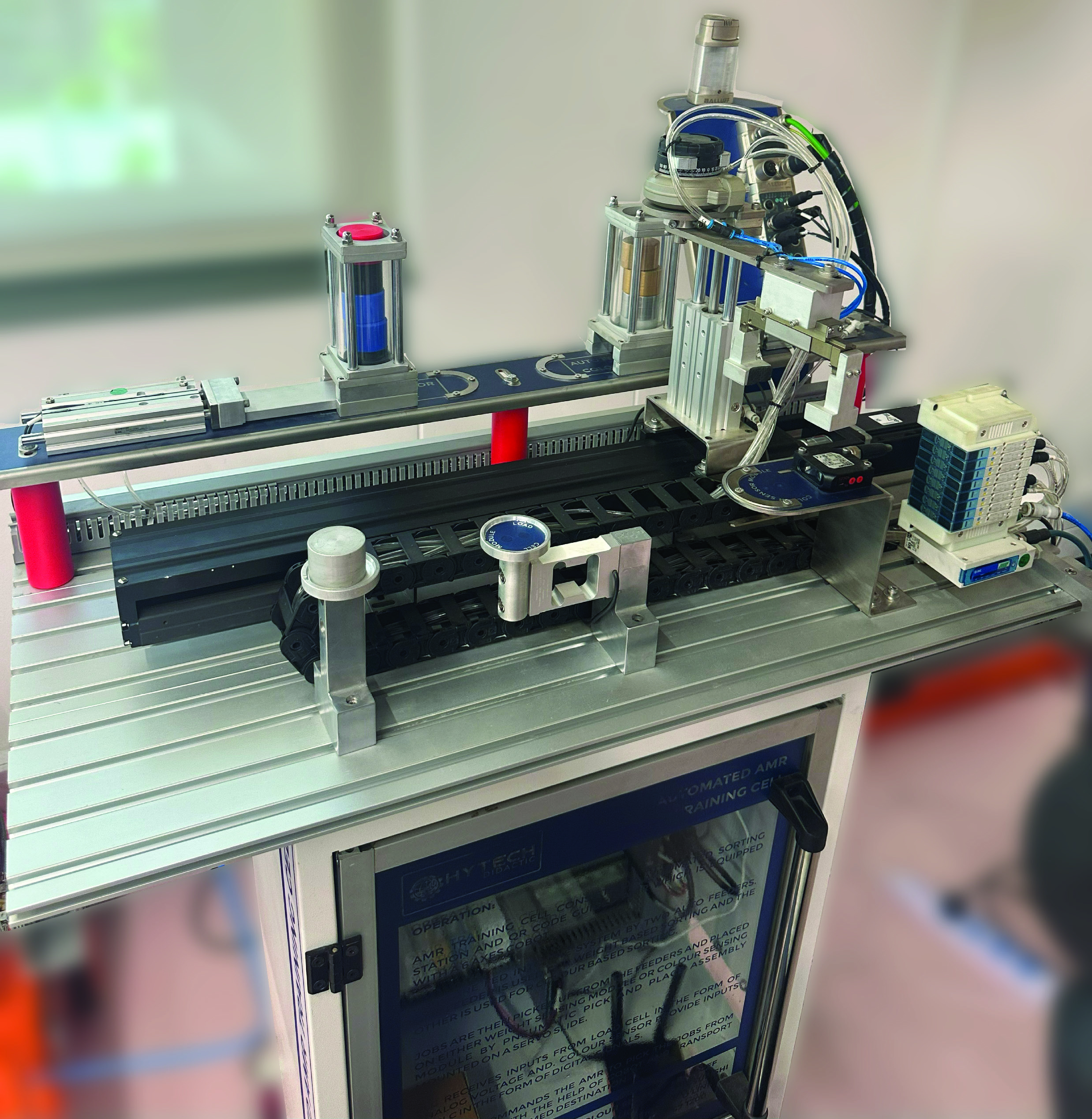

Automation station is a mechatronics based station designed to carry out colour based and weight based sorting of components. Once the sorting is completed, AMR is supposed to transport sorted job to desired position with the help of COBOT and Vision system.

Hytech Didactic AMR Training cell is designed to provide hands on experience to students on industrial AMR applications and its integration with industrial automation components such as COBOT and PLC – HMI.

This training cell mainly consists of following major components:

1. AMR equipped with a 6 axes COBOT mounted on the top

2. Automation cell equipped with Colour based sorting and vision based sorting with direct integration with AMR

User is expected to carry out programming of not only AMR but also COBOT and industrial automation cell through PLC and HMI. User is also expected to integrate AMR and COBOT with Automation cell.

| Process | |

|---|---|

| 1 | User should carry out automated sorting process of jobs on automation station based on their colour or on their weight. |

| 2 | Once the sorting is completed, signal should be passed on to the AMR |

| 3 | AMR should then travel to the automation station from its parking bay |

| 4 | With the help of COBOT mounted on AMR, user should pick up the job from the automation station |

| 5 | AMR should travel to its destination and place the job on predefined location |

| 6 | Entire process should be demonstrated and virtually simulated using a digital twin software on EnMechatronics concept designer or similar simulation software |

| Detailed Technical Specifications: | |

| Industrial Automation Cell with PLC and HMI: | |

| Structure | Aluminum Profile based worksurface with minimum dimensions of 1000 x 540mm |

| Panel in fabricated mild steel with 4 castor wheels | |

| Door latching switch for electrical panel | |

| Panel made in mild steel with minimum dimensions of 600mm x 400mm x 700mm (Ht) on which the aluminium work surface is mounted | |

| Automation Control | Siemens S7 1200 PLC |

| Siemens KTP 700 HMI | |

| 5 Port Unmanaged Switch | |

| I/O Link based Master with minimum 8 Ports | |

| Smart Light for operation indication | |

| Valve bank with 8 Solenoid Valves (5/2 Double Acting Solenoid valves) | |

| Colour Sensor with 3 colour detection | |

| Load Cell with amplifies, Resolution: 10 Grams, Maximum Load: 10 KG | |

| Feeder Mechanism | Auto Feeder Assembly with Guided Cylinder for automatic feeding of load sensor jobs |

| Auto Feeder Assembly with Guided Cylinder for automatic feeding of colour sensor jobs | |

| Single Axis Robot (Linear Slide) | Linear slide with Ball screw with minimum travel of |

| Sensor Pack for linear slide (1 x Inductive Proximity, 1 x Capacitive Proximity, 1 x Retroreflective Photosensor) | |

| Reed Switches (10 Qty) for pneumatic Cylinders | |

| Pneumatic Rotary Module | Pneumatic Guided Cylinder |

| Pneumatic Rotary Motor (Vane Motor) | |

| Pneumatic Parallel Gripper | |

| AMR – Autonomous Mobile Robot | |

| AMR (Anscer / Omron / Equivalent) | |

| Includes: | |

| a. Software | |

| b. 360 Degree Safety | |

| c. Obstacle Avoidance | |

| Manual Charger for AR100 AMR | |

| Battery for AMR | |

| Barcode based sensing for +/- 10mm accuracy | |

| Android Based Tab for AMR Operation | |

| Payload Capacity of minimum 100 KG | |

| COBOT with 6 Degrees of Freedom | Number of axes: 6 |

| Load capacity (max.): 2 kg | |

| Repeatability: ±1mm | |

| Reach: max. 664 mm | |

| Nominal reach: 400 mm | |

| Dynamics with 500 g load capacity: min. 7 picks/min | |

| Net weight: 8.2 kg | |

| Control system: plug and play or open source version | |

| Electrical Gripper for COBOT | Stroke per jaw [mm] | 8 |

| Min. gripping force [N] | 54 | |

| Max. gripping force [N] | 215 | |

| Recommended workpiece weight [kg] | 1.05 | |

| Max. permissible finger length [mm] | 64 | |

| Max. permissible weight per finger [kg] | 0.14 | |

| Repeat accuracy (gripping) [mm] | 0.02 | |

| Closing time [s] | 0.21 | |

| Opening time [s] | 0.21 | |

| Weight [kg] | 0.51 | |

| Controller electronics | integrated | |

| Communication interface | Digital inputs | |

| Number of digital inputs | 2 |