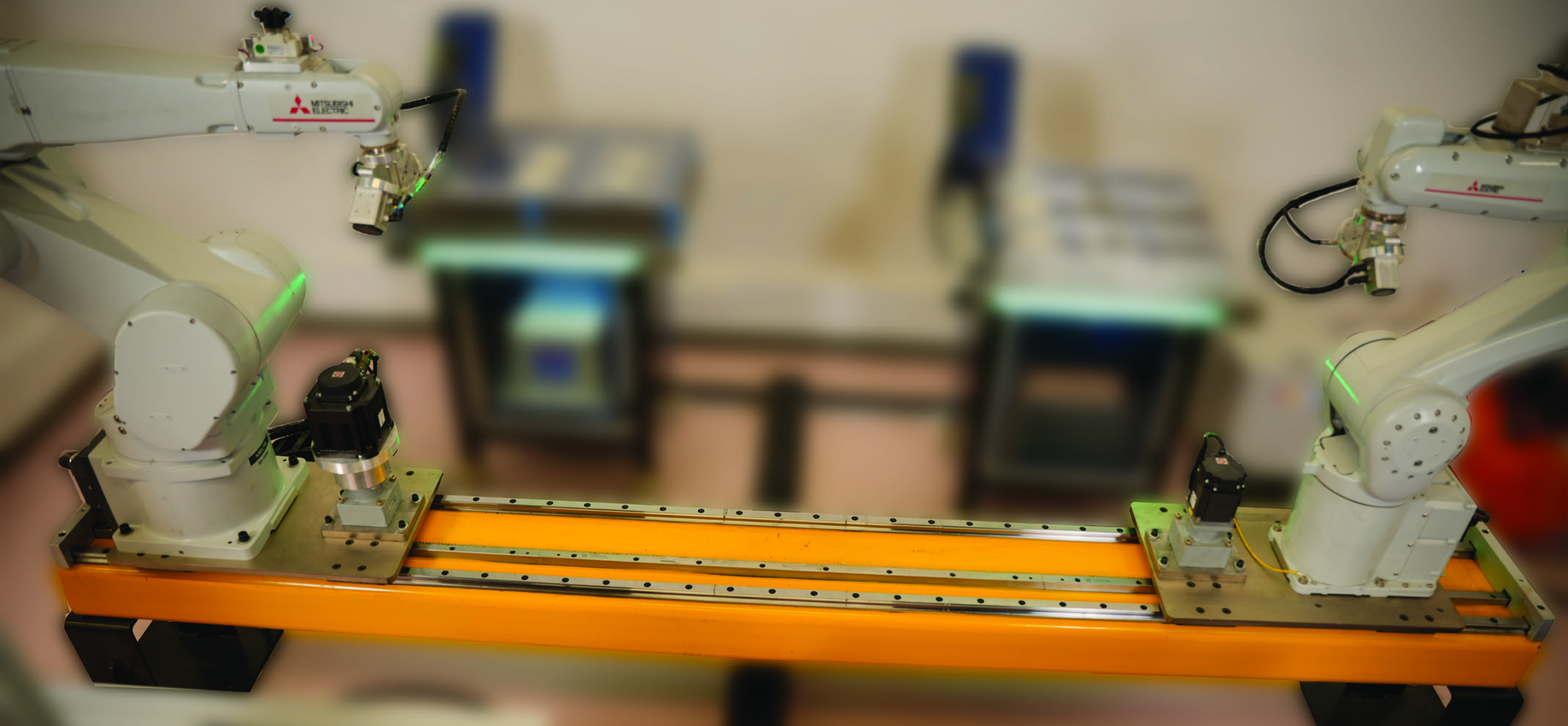

Integrated Deburring, Polishing And Engraving Cell With Dual Robots

Hytech Didactic integrated Robotic Cell with Dual Robots is equipped with two 7 axes robots. This cell provides hands on experience to user on industrial integrated robotics applications.

User is expected to program both robots in such a way that they work in collaboration with each other to carry out industrial processes such as deburring, polishing and engraving. Four different stations are provided to carry out various processes including storage, retrieval as well as vision inspection.

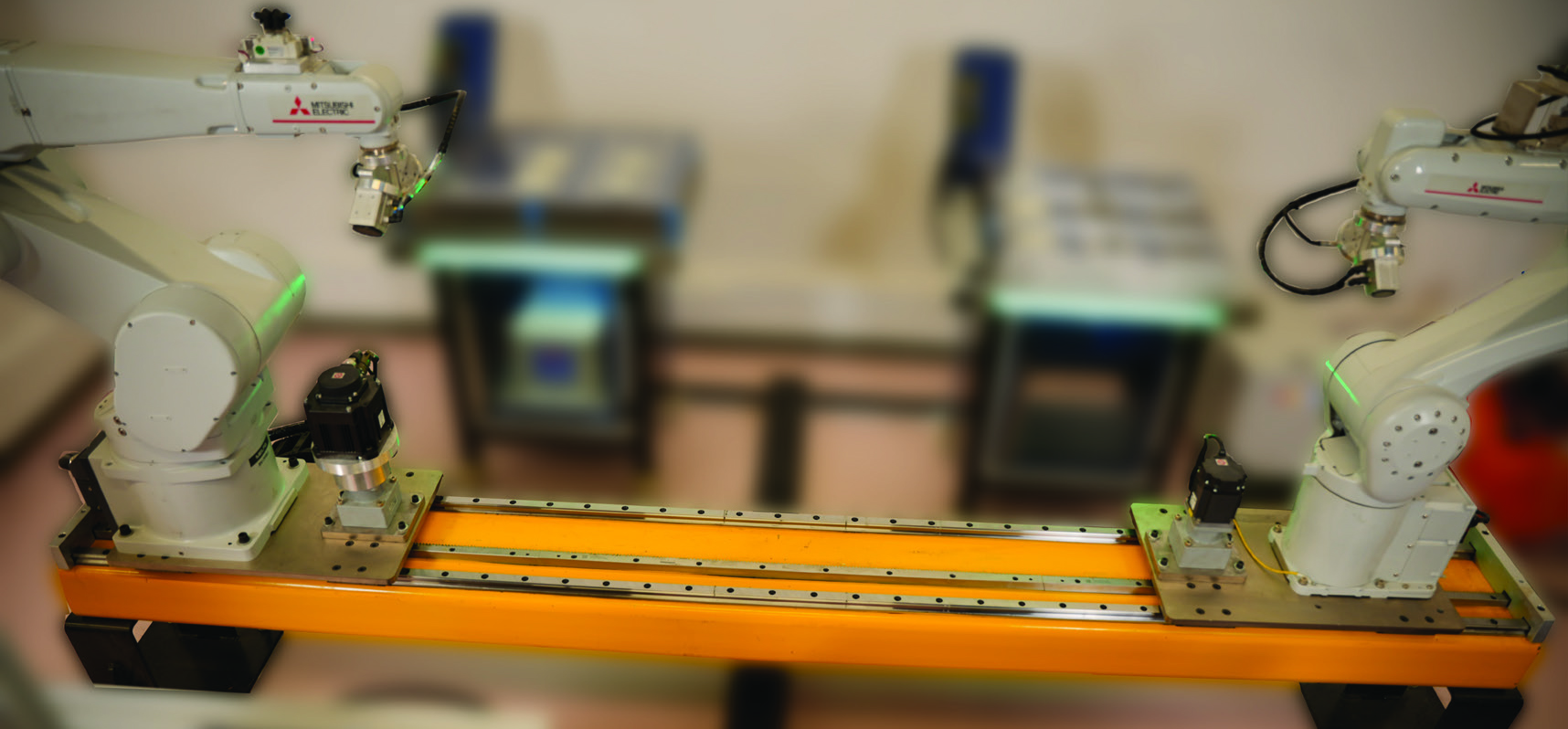

User is exposed to various industrial processes such as robot frame and tcp integration for effective operations. Seventh axis of a robot is a linear gantry axis which is controlled form robot teach pendant as an interpolated axis. Gantry provided in this cell is an industrial gantry with linear motion guideways, rack – pinion and planetary gear box.

The industrial Robotic process includes pick up of the job from storage by a robot and detecting its shape through vision inspection. Depending on the input received from vision system, first robot carries out the deburring application and second robot can carry out the polishing application. Depending on user requirement, second robot can carry out engraving application. Both robots can work collaboratively to reverse the job.

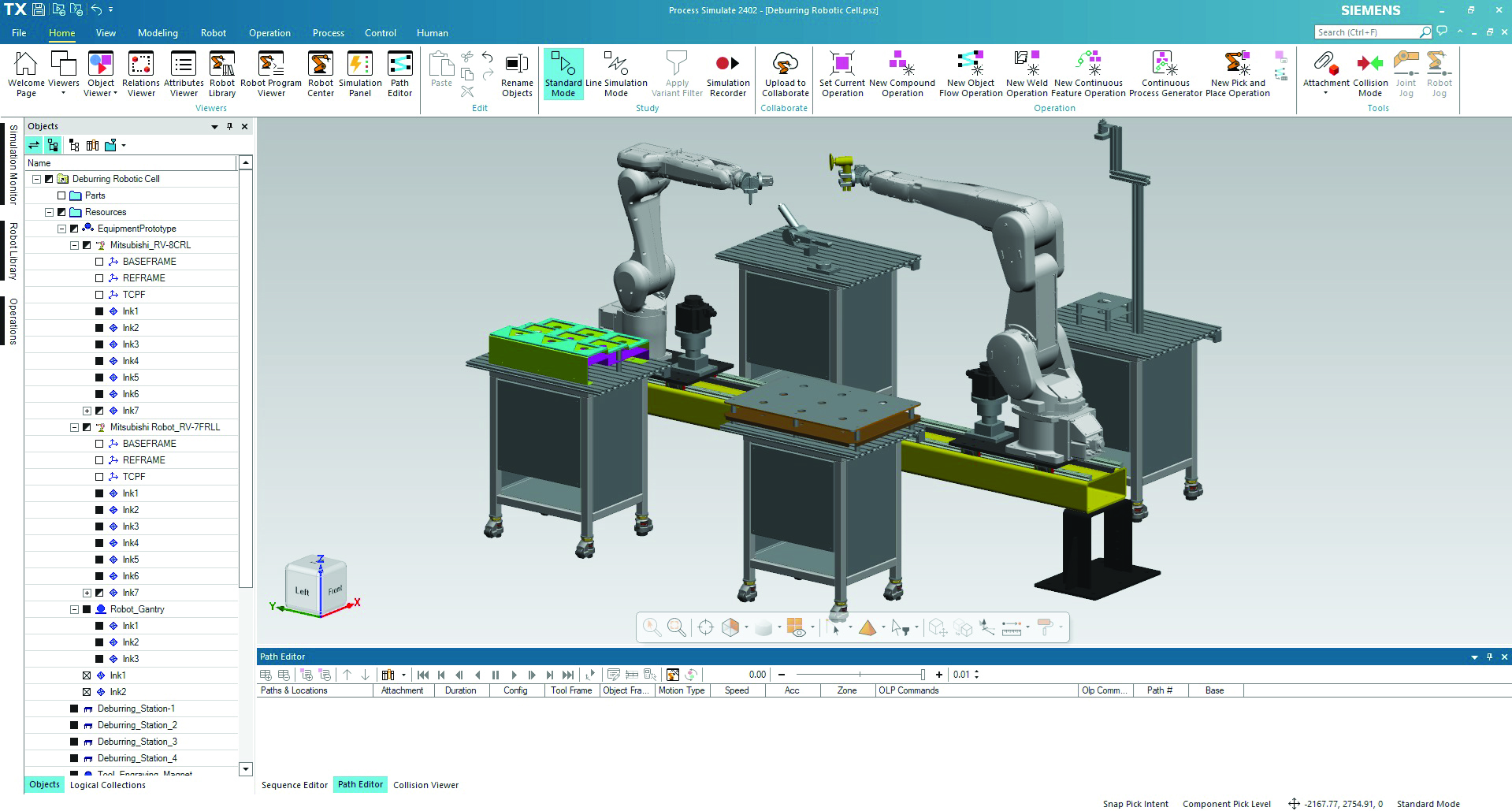

With this state of the art robotic cell, users are exposed to latest integrated robotic programming by integrating two robots, PLC, HMI and SCADA. Users can also utilize various offline programming software such as Siemens Technomatix to carry out complex robotic programming and avoid collision.

Integrated Robotic cell for deburring, polishing and engraving provides unique experience in dual robot operation which are coupled with each other and mounted on the same gantry. Each robot is a 7 axes robot with 7th axis being a linear gantry axis.

Vision provides additional advantage in industrial robotic integration

| Process | |

|---|---|

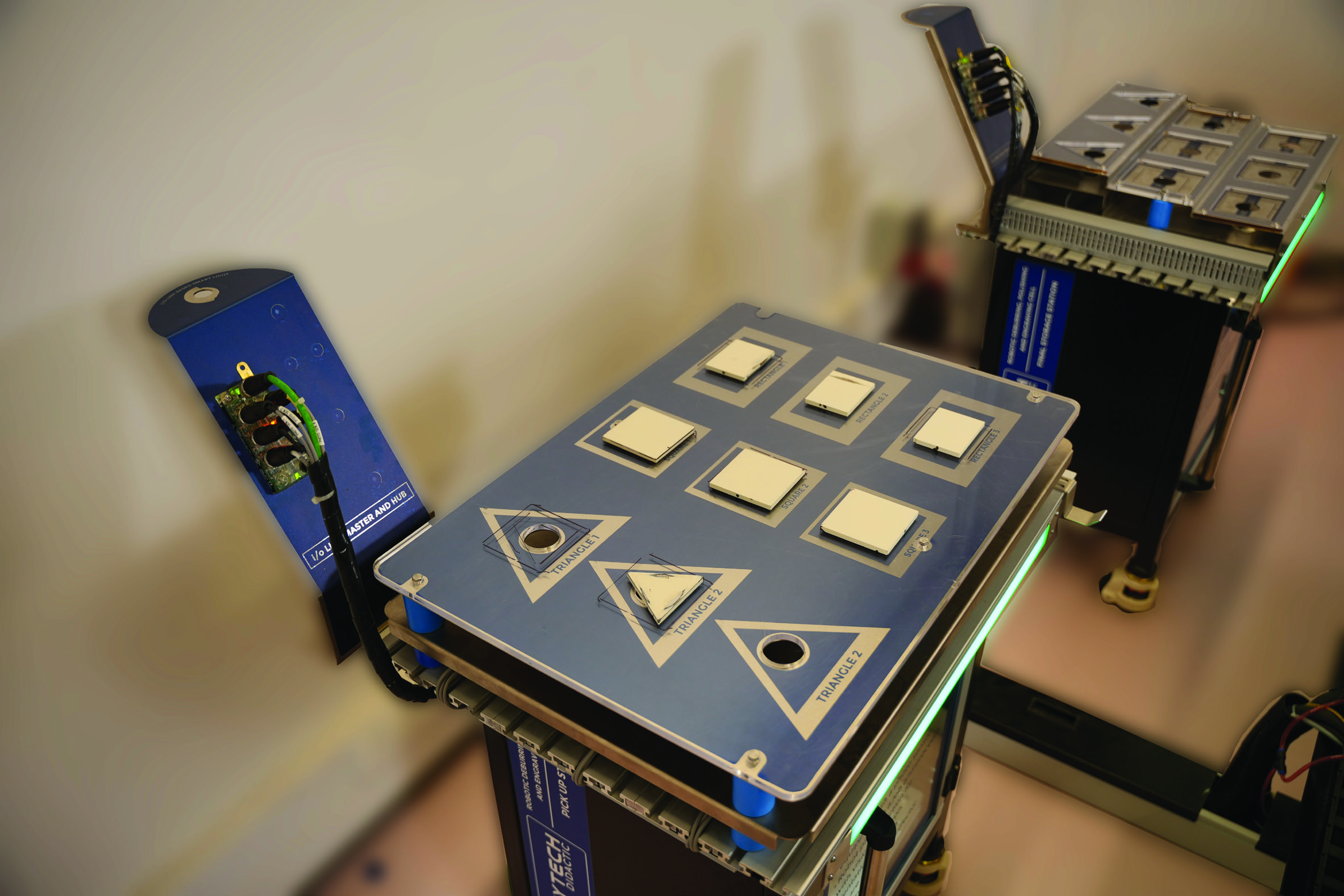

| 1 | Robot 1 with minimum reach of 1500mm picks up the raw job from Station 1. Each cell in station 1 is equipped with photosensor. |

| 2 | Root 1 which is equipped with electromagnet as an end effector places the job in vision module to find out the exact shape as well as orientation of the job. |

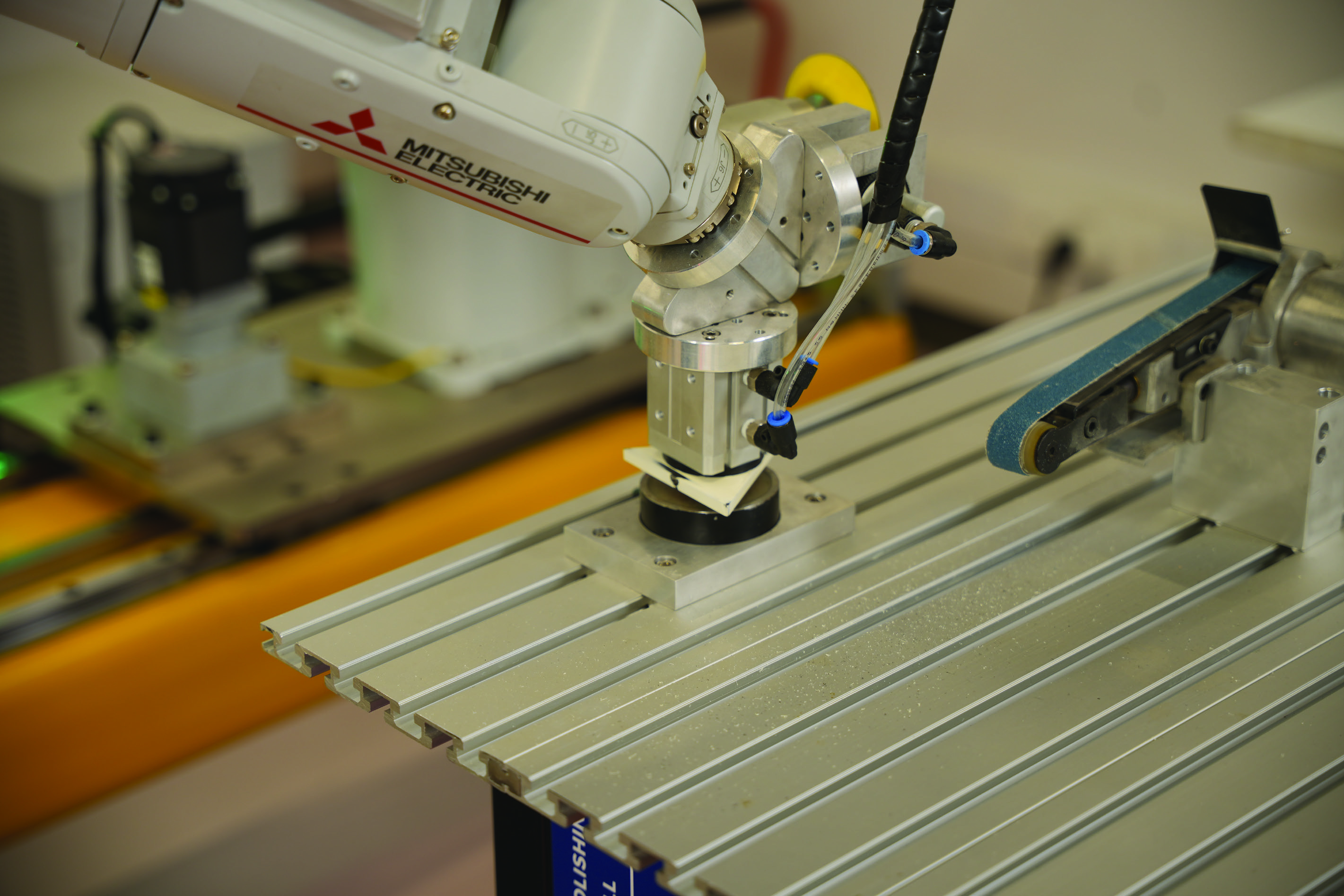

| 3 | Depending on the input from vision system, Robot 1 carries out the deburring application on the next station |

| 4 | After deburring, robot 1 places the job on electro magnet and carries out polishing process. |

| 5 | Robot 2 with minimum reach of 700mm then picks up the job with electromagnetic gripper and holds it in a position where Robot 1 can carry out polishing application. In this way, both surfaces of a job can be polished. |

| 6 | Robot 2 places the job on electro magnet and carries out engraving applications. |

| 7 | Robot 1 then picks up the final job and places it in storage station. |

| Technical Details | |

|---|---|

| Station 1 | Equipped with storage units to place raw objects of various shapes. Each cell is equipped with a photosensor for dynamic feedback. I/O Link connectivity between station and CCU unit is provided with profinet communication. |

| Station 2 | Station 2 is equipped with vision system from Cognex which can sense various shapes and provide feedback to CCU as well as Robot controller. |

| Station 3 | Station 3 is equipped with deburring tool mounted rigidly on the station. Electromagnetic fixture is also provided on station 3 separately. User can mount the raw job on this electromagnetic fixture to carry out the polishing as well as engraving applications. |

| Station 4 | Station 4 is a storage unit where all processed jobs are stored. Each cell on the storage unit is equipped with photosensor with dynamic feedback to CCU station. I/O Link connectivity between station and CCU unit is provided with profinet communication. |

| Experiments | |

|---|---|

| 1 | Integrated Robot operation (Coupled Robots) |

| 2 | Flipping of jobs with dual robots |

| 3 | PLC and coupled robot integration |

| 4 | SCADA Integration |

| 5 | Dual end effector operations for each robot |

Robot 1:

Robot 1 is a 7 Axes Robot with 7th axis being the linear gantry axis controlled directly from the Robot teach pendant. Robot 1 is equipped with two end effectors. First end effector is with electromagnetic gripper and second end effector is a pneumatically powered polishing tool. Both end effectors are pneumatically powered with solenoid valves operated directly from the Robot controller with CCU integration. Payload capacity of Robot 1 is minimum 7 KG and reach is minimum 1200mm.

Robot 2:

Robot 2 is a 7 Axes Robot with 7th axis being the linear gantry axis controlled directly from the Robot teach pendant. Robot 2 is equipped with two end effectors. First end effector is with electromagnetic gripper and second end effector is a pneumatically powered engraving tool. Both end effectors are pneumatically powered with solenoid valves operated directly from the Robot controller with CCU integration. Payload capacity of Robot 2 is minimum 7 KG and reach is minimum 800mm.

Robot Gantry:

Robot 1 and Robot 2 are mounted on the gantry system which is an industrial gantry with rack pinion and linear motion guideway attachment. Each Robot is coupled with the gantry through planetary gearbox. Minimum travel of gantry axis is 2,500mm.

Central Control Unit:

Central Control Unit (CCU) is a central control station equipped with Siemens S7 1500 PLC and workstation for cell operation. CCU Workstation is equipped with SCADA as well as digital twin software for offline programming. Dual monitors provide user with ease as well as convenience in PLC as well as SCADA and Robot programming.

Software in CCU:

Siemens SCADA – Developer (WinCC Advance) – Perpetual Software

Mitsubishi RT Tool box / Fanuc Roboguide – Perpetual

Siemens Technomatix – Perpetual with dynamic integration for process simulation

SCADA Runtime for user operations

Offline Programming and Digital Twin Integration:

With this state of the art robotic cell, users are exposed to latest integrated robotic programming by integrating two robots, PLC, HMI and SCADA. Users can also utilize various offline programming software such as Siemens Technomatix to carry out complex robotic programming and avoid collision.