PLC and HMI Training Kit - Advance

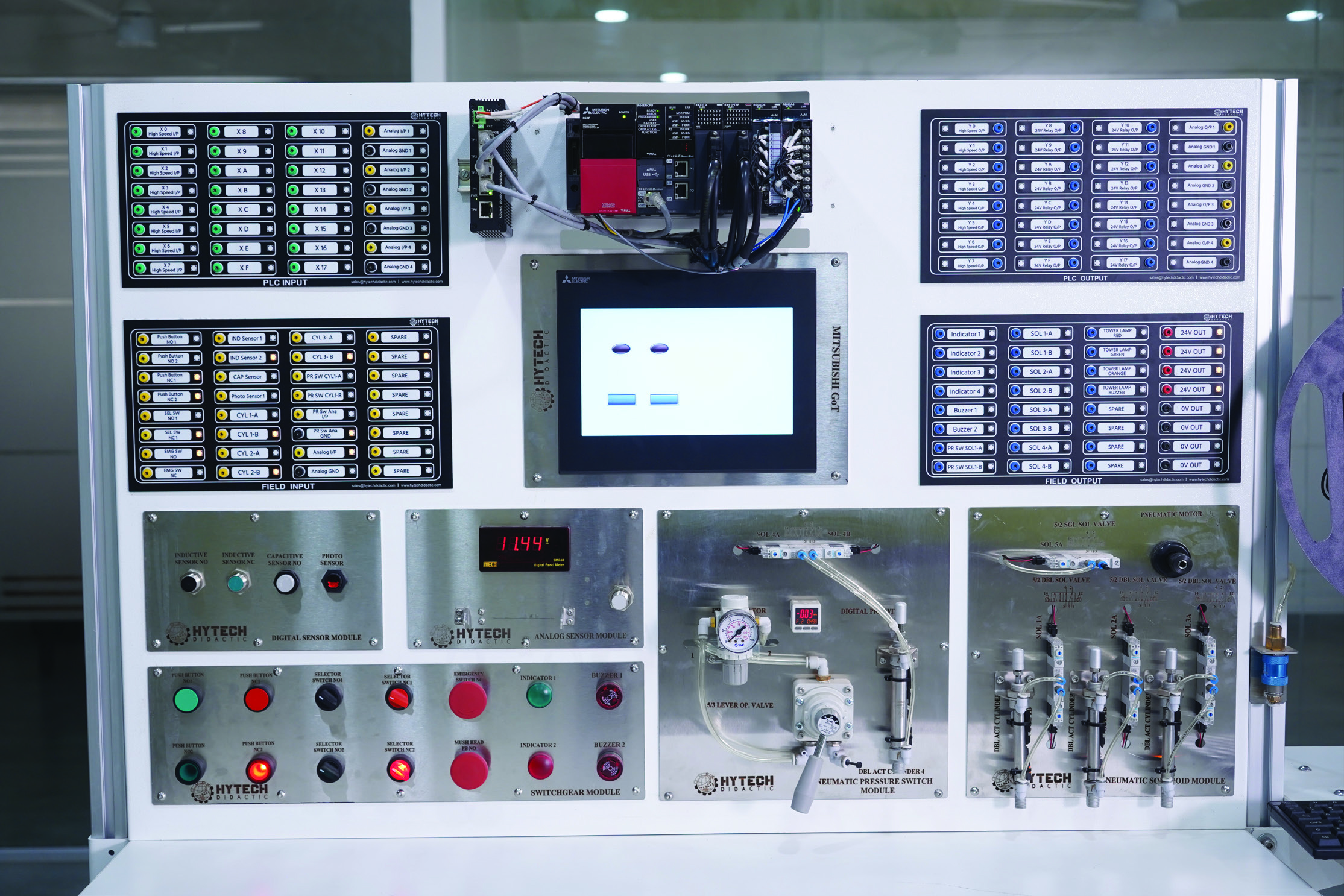

Hytech Didactics’ PLC and HMI Training kit is ergonomically designed to provide detailed training on latest industrial PLCs and HMIs. Advance model is equipped with advance PLCs such as Siemens S7 1500 or Mitsubishi IQR PLC.

Specially designed input and output modules are provided with necessary safety arrangements to avoid damage to PLC or HMI during operation by inexperienced users or students. Input and Output modules allow users to connect the relevant field component with specified PLC input or output with the help of patch chords. This makes the whole system flexible providing necessary ease of operation.

The PLC and HMI Training kit is provided with Castor wheels and mounting arrangement. The structure is made in powder coated mild steel providing it with necessary strength. Ergonomic arrangement for workstation mounting is provided with monitor mounting stand. Connector based wiring makes the wiring easily understandable to users.

The Hytech PLC and HMI Training kits is equipped with real time industrial automation components. Participants can integrate various modules with PLC, HMI and workstation to operate them as per the requirement.

Separate Field and PLC Connection modules makes it possible for users to integrate external automation components.

Industrial Automation Modules:

Industrial Automation modules are individual units which can be integrated with PLC and HMI Training Kits. Different automation modules provide hands on experience on latest industrial technologies to users. There are dynamic modules as well as static modules which can be integrated with the training kit. Dynamic Automation modules are provided with actual industrial automation components such as sensors, servo motors etcetera. Static Automation modules represent various industrial processes which can be operated in integration with PLC and HMI.

User can integrate additional modules as well depending on their requirements.

Dynamic Automation Modules:

| Sensor Module - Digital | Pneumatic Pressure Switch Application (Analog Control) |

| Sensor Module - Analogue | AC Motor Speed Control through VFD and PLC using HMI |

| Switchgear Module | Temperature Control Module (Analog Control) |

| Pneumatic Operation with Solenoid valves and Cylinders | Conveyor Control Module |

| Stepper Motor Module | Load Cell with Digital Display Module (Analog Control) |

| Servo Motor Module | Flow Sensor Module (Analog Control) |

| AC Motor and Encoder |

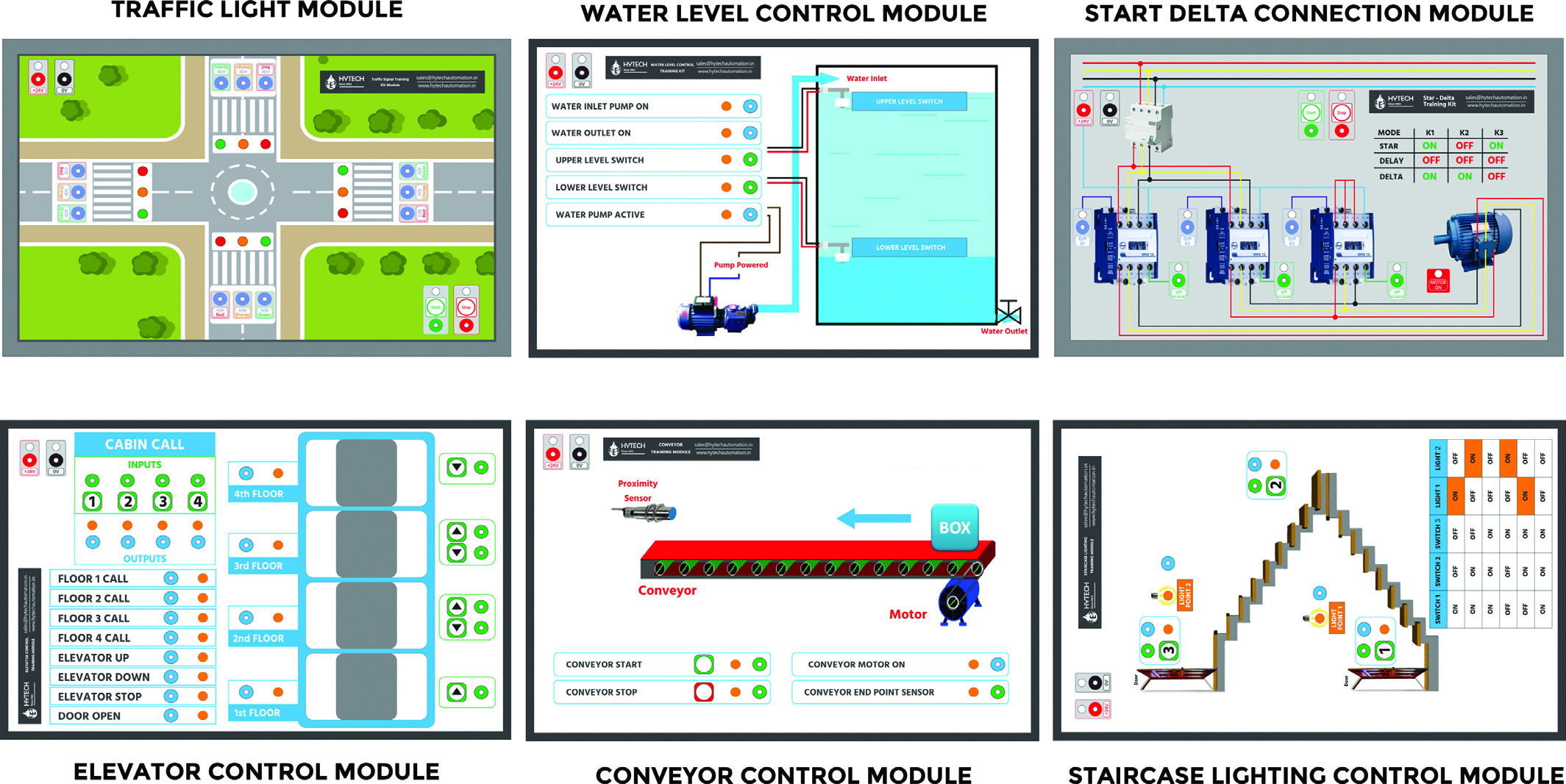

Static Automation Modules:

Static Automation modules are provided to expose users to actual industrial applications of PLC and HMI.

These static automation modules represent various industrial processes which can be operated in integration with PLC and HMI. Banana connections are provided on static automation modules for PLC input and output connections. Depending on the user's requirement, various static modules are supplied along with PLC - HMI training kits.

| Star Delta Module for Motor Operation | Traffic Signal Operation |

| Water Level Controller | Staircase Lighting |

| Elevator Operation | Conveyor Operation |

Major Components

| PLC and HMI | Siemens S7 1500 - KTP 700 Comfort / Mitsubishi IQR 04 - GT 2107 |

| PLC Accessories | SMPS |

| Unmanaged Switch | |

| Automation Modules mounted on the Structure | Digital Sensor Module |

| Switchgear Module | |

| Pneumatic Solenoid Module | |

| Pneumatic Pressure Switch Module | |

| Dynamic Automation Module | Servo Motor Module |

| AC Motor and Encoder | |

| Pneumatic Pressure Switch Application (Analog Control) | |

| AC Motor Speed Control through VFD and PLC using HMI | |

| Temperature Control Module (Analog Control) | |

| Conveyor Control Module | |

| Load Cell with Digital Display Module (Analog Control) | |

| Flow Sensor Module (Analog Control) | |

| Static Automation Module | Star Delta Module for AC Induction Motor Operation |

| Traffic Signal Operation | |

| Water Level Controller | |

| Staircase Lighting | |

| Elevator Operation | |

| Conveyor Operation |